At first glance, mica bands may seem superior, but the ease of installation of ceramic bands cannot be overstated. Over time, machines often become dirty and damaged, the surface becomes rough, which can lead to improper installation (air pocket between the band and the barrel). The result is poor contact with the surface to heat. Those factors reduce mica band heat transfer and operating life, but have next to no effect on ceramic bands which are heating the air.

Construction of a heater band

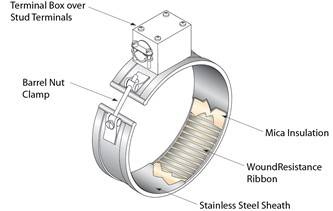

Mica band heaters are made of a resistive ribbon (or wire) wound around a mica sheet and electrically insulated with 2 or more mica sheets. This mica assembly is enveloped with a metal sheath and formed in the desired shape.

Mica bands transfer heat by conduction from the band directly to the surface to be heated. Mica band internal temperature is limited to around 480°C.

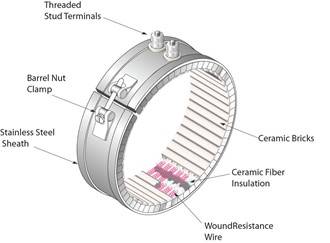

Ceramic band heaters are made of a resistive wire coiled and inserted in the holes of ceramic pieces for electrical insulation. The ceramic assembly is attached under a sheet metal cover and formed in the desired shape.

Ceramic band heaters transfer heat by infrared radiation through the air to the surface to be heated, theoretically requiring no physical contact. Ceramic band internal temperature is limited to around 900°C.

Pros of mica bands over ceramic bands are as follow:

- Mica bands can typically achieve equal or higher watt density than ceramic bands for operating temperatures in the range required for the plastic industry.

- Mica bands are highly customizable: holes and slots can be added with little constraints and the shape can be a circular band at diameters down to 1.00", a flat plate with or without bends, a conical band, etc. Ceramic bands are limited by the fixed-dimension ceramics used and cannot be conical, with diameters under 2.50" potentially problematic.

- Mica bands are thin, typically between 0.12" and 0.19" thick. Ceramic bands are usually between 0.40" and 0.75" thick.

- Mica bands are cheaper than ceramic bands and lighter.

Pros of ceramic bands over mica bands are as follow:

- Since heat is transferred by infrared radiation, the contact between the band and the surface to be heated is not that important, requiring less tension on installation. With mica bands, both surfaces need to be smooth & clean and the band needs to be well seated & tightened, otherwise heat transfer will be reduced and the band risks overheating. This makes the installation of ceramic bands much more fool-proof and reliable.

- When properly de-rated, ceramic bands can achieve higher operating temperatures.

- Ceramic bands can be repaired, which involves replacing the ceramic assembly and reusing the rest if undamaged. Our prices are 30% cheaper than for a new band with the same lifespan and can also be repaired multiple times.

Skip site navigation

Skip site navigation