Band heaters: What type and Where?

We must distinguish between the different types of band heaters and where to install them on the cylinder to be heated.

Since band heaters are mostly used in the injection and extrusion fields, we’ll focus on them.

Mica band heater

The mica band heater is the most common. Also the less expensive. Used at the end of the cylinder (i.e. extruder’s screw head), it is ideal when no thermocouple hole or notch are present on the band. Otherwise, we use a mineral band heater in that area.

|

Mica band. The internal construction is not the same as a mineral but visually what's differentiate a mica from a mineral is the fold-over of the sheet in front of the band. |

Mineral band heater

You can recognize a mineral band heater by the fact that it is completely sealed on the outer face and the fold-over of the sheet is on the inner face of the band. Internal contamination by plastic is therefore less probable since the mineral material inside is applied in layers over the mica and the resistive wire.

Another advantage with this type of band, you can substantially increase wattage versus a mica band and speed up preheating. However, this type of band is more expensive.

|

The mineral band is completely sealed on the outer face and, if a thermocouple hole is present, it will be totally sealed as well, to avoid contamination of the internal design. |

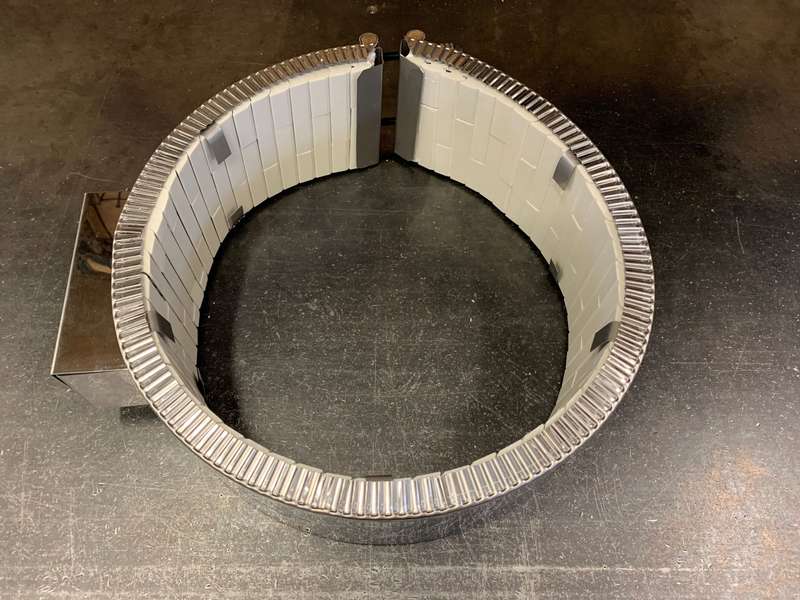

Flexible mica band heater

This mica band heater has teeth on the fold of the edge of the band. This option is interesting on bands 6” and less in diameter; any wider, you run the risk of creating a stress on the internal design. Also think about that option if you remove your bands often. A 2-part band heater is also a good choice. The mica flexible band cannot be installed at the end of the cylinder, too risky for contamination but a little further down.

|

Flexible mica band with a quick latch and trunion for the tightening which allows quick installation/uninstallation. |

Ceramic band heater

The ceramic band heater, unlike the aforementioned bands, can heat the air through radiation. Hence, less risk of breaking if the band is not in good contact with the cylinder’s surface.

Also, with the right internal design, the ceramic band can heat at higher wattage than mica. It is ideal on the second part of the cylinder and using an insulation blanket when possible is a good idea. The ceramic bands last longer than mica bands. So, when there’s no risk of contamination (dust,plastic,oil or other), ceramic band heaters are a good choice.

|

Ceramic band heaters have an insulating ceramic fiber layer inside, whose thickness can be increased up to 3/4'. |

Skip site navigation

Skip site navigation