- Features

- Applications

- 3D Drawing configuration tool

- Termination types

- Tips

- Box

Features

Mica heating plates are high-performing and reliable heating elements, designed to offer excellent thermal conductivity. They are manufactured to your specifications in our factory and can be customized to meet the specific needs of each project.

Technical Features

General Features:

- The internal surface of the band is made of aluminized steel to ensure better heat conduction, while the external surface is made of stainless steel.

- Standard thickness of 3/16'

- Maximum operating temperature of 600 °F

- Single-phase or three-phase

Optional Features:

- Special configurations available: Triangular plates, trapezoidal plates, U-shaped plates, etc.

- Pressure plates are available in thicknesses of 1/8', ¼' or ½' (to prevent the plate from warping with use). It is important to note that pressure plates also allow to increase the number of watts/sq in.

- CSA & UL

- Special cold parts

- Thermocouple holes

- Notches

- Mounting holes

- Irregular shaped holes

- Insulating wool included as an option

- Uniform heat (more density at the ends if needed)

- Dual voltage if necessary

- Also available with grounding and integrated thermocouple

- With folded ends to prevent any contamination (Fold-over)

Applications

Common Applications

- Heating of flat surface parts

- Cooking and keeping food warm

- Vulcanization

- Heating of outdoor panels (strip heaters)

- Heating cabinets

- Packaging equipment and many other industrial applications

3D Drawing configuration tool

Volton offers you the possibility to create your 3D plate heater and send it to us! We encourage you to follow the tutorial to help you get the best of this tool : https://voltondesign.com/

Termination types

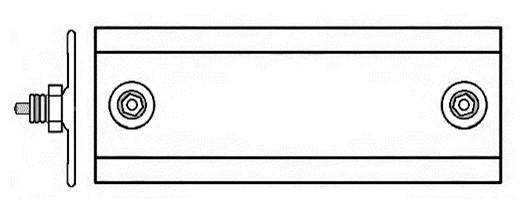

|

Type K One post terminal at each end |

|

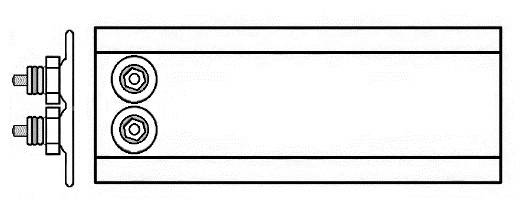

Type L

Two post terminals at one end |

|

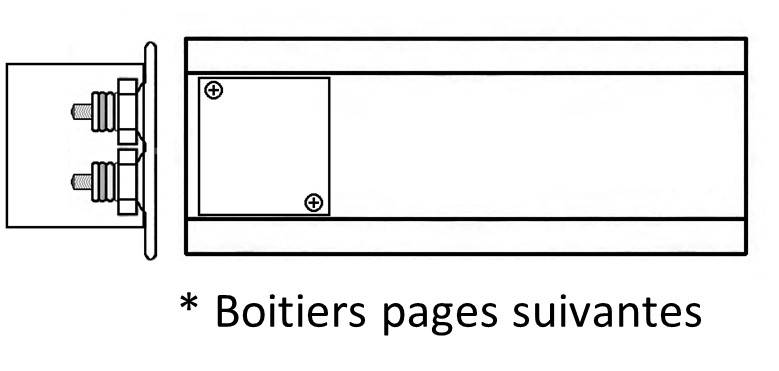

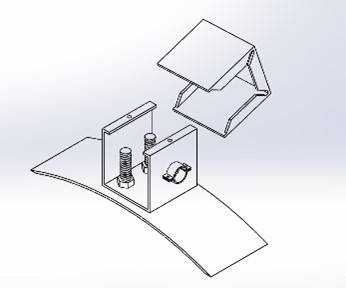

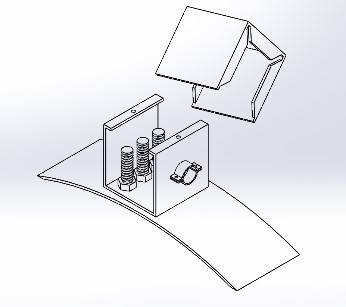

Type M Terminal box * |

|

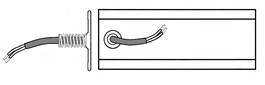

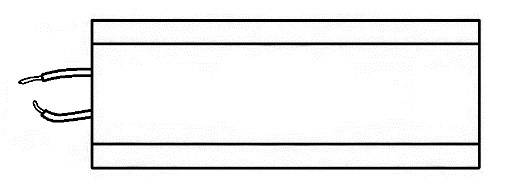

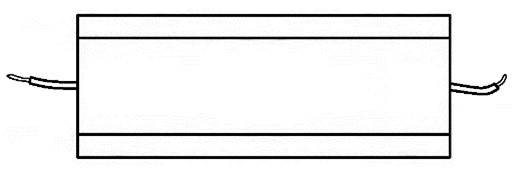

Type N High temperature leads protected by a spring at one end |

|

Type O Two separate high temperature leads at one end |

|

Type P One high temperature leads at each end |

* Connection boxes on next tab

Sleeves

|

Stainless steel braid (SSB) |  |

Armor cable (BX) |

Tips

- The heated area has to be clean with no residue and have a flat surface.

- It is very important that the strip heater is installed in "sandwich" between 2 pressure strips or strongly tightened with a mounting screw to avoid the creation of air pockets between the strip heater and the pressure strips insure a better heat transmission Volton manufactures on demand those strips with the thickness you wish in order to incorporate them to your strip heaters.

- Verify the thickness of the strip heater on the heated area after the first heat and tighten again if needed.

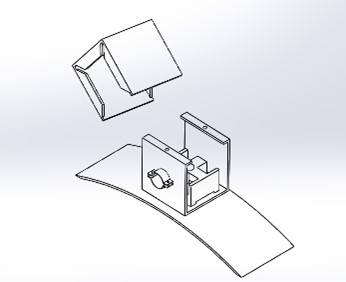

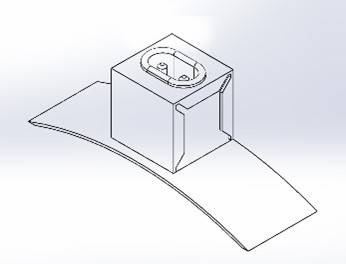

Box

Standard box with post terminals :

|

1 phase 2' x 2' x 1,75' |

|

3 phases 3,25' x 2,5' x1,75' |

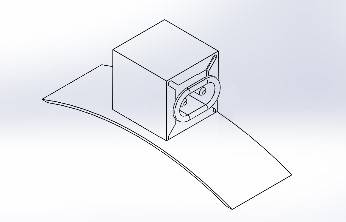

Junction box:

|

2' x 2' x 1,75' |

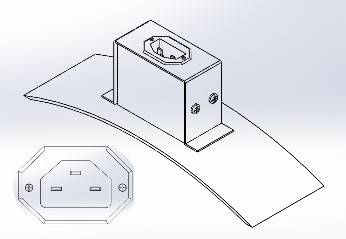

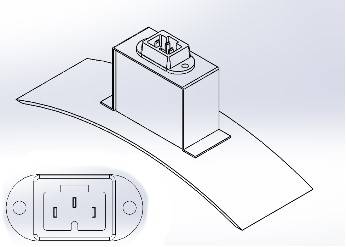

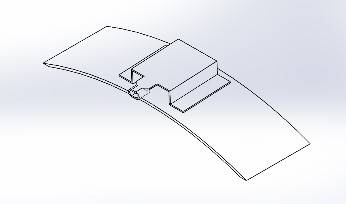

European plug:

|

On the top 1,94' x 1,02' x 2,6' |

|

On the side 2,73' x 1,58' x 1,02' |

|

Direct 1,73' x 1' x 0,97' |

Horizontal 3 pins plug:

|

2,35' x 1,48' x 2,62' |

Vertical 3 pins plug:

|

2,25' x 1,20' x 2,30' |

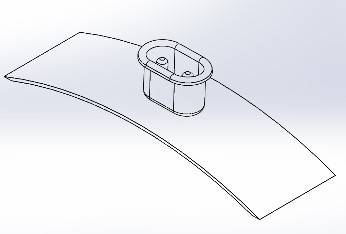

Low profile box:

|

1,42' x 1,75' x 0,45' |

Skip site navigation

Skip site navigation