- Features

- Applications

- 3D Drawing configuration tool

- Termination types

- Tips

- Box

- Fixation

Features

Mica heating bands stand out for their ability to be designed and used in a wide variety of environments, making their use highly adaptable. These high-performance heating elements are specifically manufactured by Volton to meet the particular requirements of each project, thus providing uniform heat. Moreover, they can be custom-made to match all shapes and dimensions, allowing optimal adaptation to all types of environments.

Mica heating bands have been manufactured in our Montreal-North factory for over 50 years.

Technical Features

General Features:

- 35W/po2 max.

- Single-phase or three-phase

- Dual voltage

- Flexible band

- Uniform heat (More heat at the ends of the band)

- Integrated thermocouple

- Maximum operating temperature 600°F

- Made of either aluminized steel, ensuring better heat conduction, or stainless steel

Optional Features:

- Special configurations available: Conical bands, partial bands, internal bands (terminals coming out on the inner face of the band), 2-section, 3-section, and more for large diameters, etc.

- CSA & UL

- With hinge (180-degree fold of the opening for bands frequently disassembled)

- Grounding

- Thermocouple holes

- Notches

- Irregular shaped holes

- Mounting holes

- Thermocouple adapter 1/8NPT, 1/4NPT, M12x1.75, 3/8-19BSPP

- Clamping straps on request

- Single-phase or three-phase

- Dual voltage

- Flexible band

- Uniform heat (More heat at the ends of the band)

- Integrated thermocouple

Applications

Common Applications

- Heating of any cylindrical part

- Heating of ducts

- Extrusion and injection field

3D Drawing configuration tool

Volton offers you the possibility to create your 3D band heater and send it to us! We encourage you to follow the tutorial to help you get the best of this tool : https://voltondesign.com/

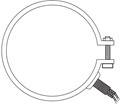

Termination types

One section

|

Type A One post terminal on each side |

|

|

Type B

Two post terminals on the same side |

|

|

Type C Spring over the leads |

|

|

Type D Terminal box |

|

|

Type T (Nozzle) Leads exit on the top of the band |

|

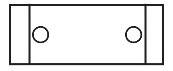

Two sections

|

Type F Four post terminals at the end |

|

|

Type G Two post terminals on each side |

|

|

Type H Spring over the leads on both section |

|

|

Type J Terminal box on both side |

|

Sleeves

|

Stainless steel braid (SSB) |  |

Armor cable (BX) |

Tips

Determine the inside diameter of your band heater as accurately as possible. A error of only 1/4" in the diameter measurement can make a difference of 3/4" on the circumference.

Tighten the screws of the Barrel-Nuts or Tabs, then tap gently with a soft mallet along the circumference to insure that the band heater is snug onto your cylinder. After a few minutes of heating re-tighten the heater.

Use several narrow width (1 ½" to 6") band heaters rather than one large one. A intensive study has shown that small narrow band heaters offer a more efficient rate of heat transfer and a longer lifespan.

To ensure that the internal electrical insulation of the band heater is not damaged, it is recommended to choose a two section (or two half-moon) heater if the cylinder on which it will be installed needs to be opened wide excessively (usually diameters over 10").

The cylinder on which the heater bands will be installed needs to have a smooth and clean surface. It is also important to avoid the accumulation of plastic residue or other contaminant on the cylinder.

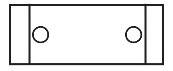

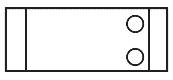

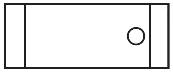

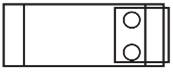

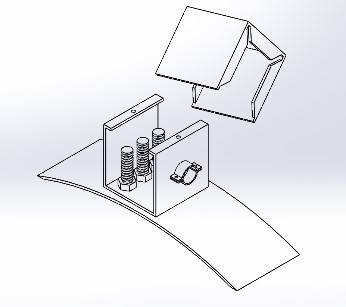

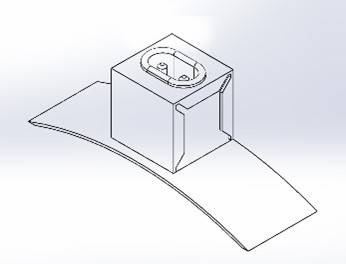

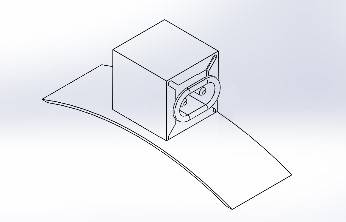

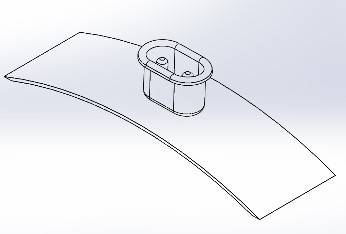

Box

Standard box with post terminals :

|

1 phase 2" x 2" x 1,75" |

|

3 phases 3,25" x 2,5" x1,75" |

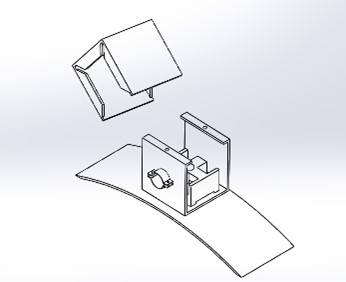

Junction box:

|

2" x 2" x 1,75" |

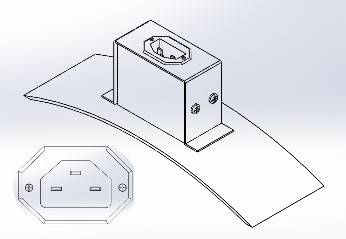

European plug:

|

On the top 1,94" x 1,02" x 2,6" |

|

On the side 2,73" x 1,58" x 1,02" |

|

Direct 1,73" x 1" x 0,97" |

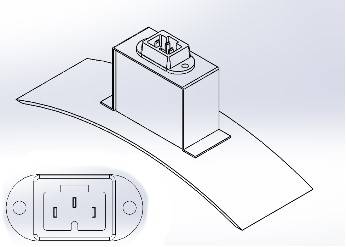

Horizontal 3 pins plug:

|

2,35" x 1,48" x 2,62" |

Vertical 3 pins plug:

|

2,25" x 1,20" x 2,30" |

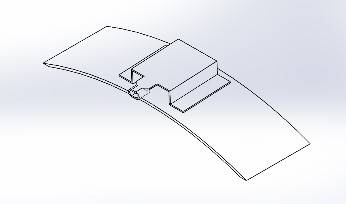

Low profile box:

|

1,42" x 1,75" x 0,45" |

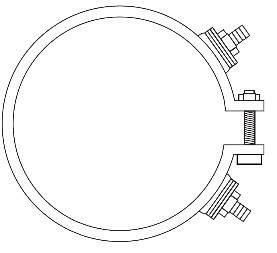

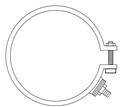

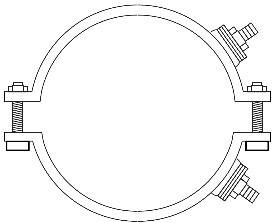

Fixation

|

Tabs/Flange |

|

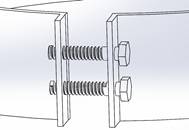

Barrel nuts |

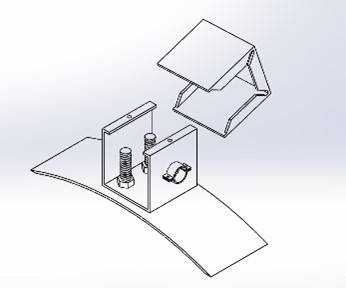

|

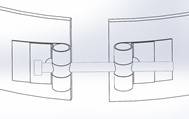

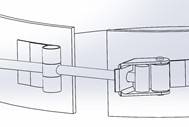

Quick latch & trunion

To quickly install and uninstall a band. When there is a lot of handling with the equipment. |

|

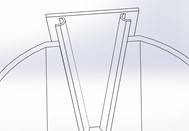

Wedges lock up

Exclusively for internal band heaters. The wedge lock-up makes it possible to maintain a constant tension between the external envelope of the heater and the surface to be heated. |

Skip site navigation

Skip site navigation