- Features

- Applications

- Termination types

- Tips

- Box

Features

Immersion heaters are heating elements designed to heat water or other liquids in tanks, containers, or basins. Once submerged in the liquid, the heating element generates heat, which is transferred to the fluid to reach the desired temperature.

Volton's immersion heaters are equipped with threaded plugs or flanges, ensuring secure installation and optimal positioning of the heating element within the tank. All our immersion heaters come with a moisture-resistant terminal box, providing optimal protection in exposed environments.

Technical Specifications

Our immersion heaters are custom-made and can be tailored to your specific heating requirements.

- With built-in thermostat or¸ thermocouple, depending on your needs

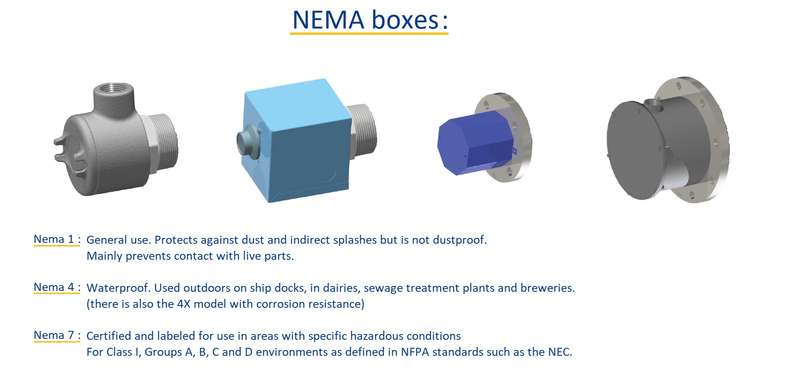

- Available with NEMA 1 or NEMA 4 enclosure (optional)

- Optional protective well (pipe insert): For applications where the heater cannot be directly immersed in the liquid

- Circulation heaters available upon request

- Available in a wide range of sheath materials (based on the solution in which the element will be immersed): Incoloy, copper, stainless steel, Inconel, Teflon, quartz, etc.

- CSA certified product (Canadian Standards Association)

Applications

Immersion heaters are essential in many industrial sectors where efficient and controlled liquid heating is required to ensure optimal production processes.

-

Liquid, gas, and compressed air heating:

Used in various industrial processes requiring fast and effective heating of liquids, gases, or compressed air for production applications.

-

Water and aqueous solution heating:

Ideal for the chemical, food, and pharmaceutical sectors, for heating water or aqueous solutions in reactors or industrial water heaters.

-

Oil and corrosive liquid heating:

Designed for demanding industrial applications, safely heating oils, special baths, and corrosive liquids.

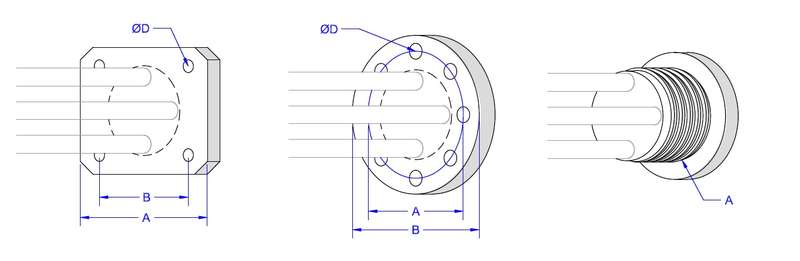

Termination types

Tips

- Using low power immersion heaters in viscous liquids or in liquids with a high density of solids could cause an accumulation of wastes on the elements.

- Immersion heaters with incoloy sheath or stainless steel can be furnished with chemically passivated sheaths, which provide really good resistance to corrosion in highly corrosive applications. Passivation is done using polishing electrolyte technique.

Box

Skip site navigation

Skip site navigation