7 reasons why your cartridges break prematurely and how to avoid it!

You question the quality of your cartridges, especially if you didn't buy them at Volton? Before switching supplier, it is important to validate that the cause of early failure is not among the following explanations.

To start with, remember that a heating cartridge heats by conduction. The stainless steel cartridge sheath must have metal to metal contact with the wall of the hole into which it is inserted.

If there is even a tiny air pocket in between the cartridge and the mold to be heated, the cartridge could burn prematurely.

1. Wrong diameter measured:

Be sure to know if the mold to be heated is in metric or imperial. Measure the hole instead of the cartridge to make certain, even though the cartridge has, technically, a 1” diameter, it is always less than 1” in order to snuggly fit in the hole. This is called the “tolerance”.

An example we often see: You measure the cartridge in imperial and you get a .982” diameter. You think this is a 1” diameter cartridge, taking the tolerance into account. WRONG. This is rather a 25 mm diameter cartridge less its tolerance. This difference in decimal will get your cartridge to burn more quickly.

1” = 0.994” approx. tolerance

25 mm = 0.982” approx. tolerance

Tolerance difference = 0.012”

Tolerance may vary from one manufacturer to the other but typically, it is from .002” to .006”.

Therefore, for a 3/8” cartridge, if you measure .369”, it means this is an imperial cartridge.

2. The hole of the mold got out of shape with time, heat and successive cartridge removal:

As the cartridge heats up, it expands and may be difficult to remove. Successive withdrawals may have damaged the hole in some places. By no longer having this perfect contact with the mold wall, air pockets are created.

To overcome this, you have 2 options:

a) We can offer special tolerances if the air pocket is really small. We call that option: “centerless grind”.

b) If the hole is really deformed/damaged, the best is to enlarge the hole to the following standard width. Ex: 3/8” hole, drill to make it a 5/8” hole.

To help remove your cartridges easily, ask for the “anti-seize coating” option.

Cartridge heater with anti-seize coating

The knock-out tab is also another very valuable option to remove cartridges whose mold is open bore, allowing the cartridge’s knock-out tab to be in open air and be struck with a rubber mallet.

Cartridge heater with knock-out tab at the extremity

You can, of course, combine those two options for an optimum removal!

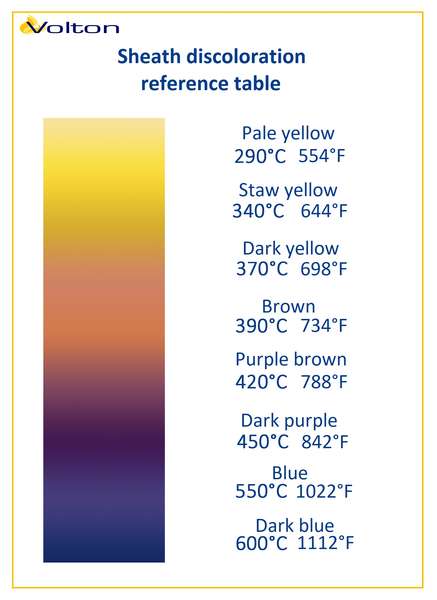

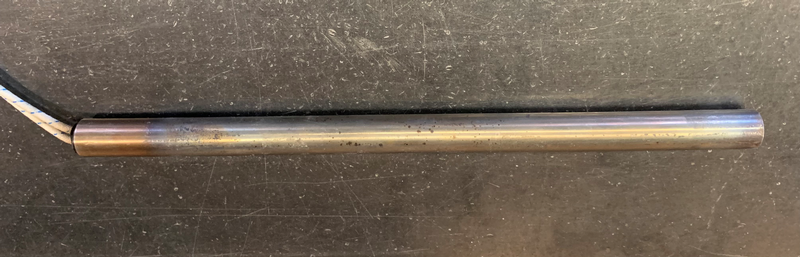

Color on the cartridge indicates temperature reached. Note that a cartridge can reach 760°C (1400°F).

On the cartridge (left), we can see that the color near the leads exit is similar to the brown and purple-brown color of the chart above. The cartridge overheated to 788°F because it did not have a good metal to metal contact with the mold.

3. Too much heat transfer compound:

If you put heat transfer compound to overcome the deformed hole problem, you must know that too much compound may also cause premature breakage since compound acts as an obstacle to the material to be heated. The cartridge needs metal to metal contact to work properly.

When needed, clean the hole from oil, dust, material and residues by using a grease remover, if necessary.

4. Lots of vibration in the application:

If the cartridge moves in the application and /or if a number of knocks per minute is generated by the equipment, this might shorten its service life.

Two solutions are available to you:

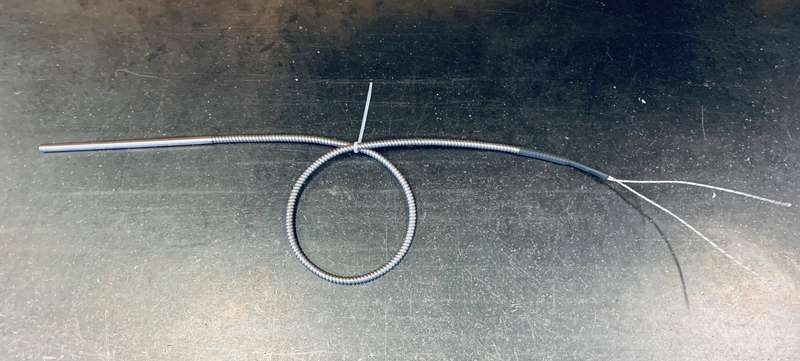

a) Check the wires movement. Perhaps a cartridge with 90 degrees exit would be necessary. If you notice that the wires break or fray, always in the same spot, namely the wire exit, a 90 degrees exit with a right angle block and a stress tube may be required. Contact us to discuss further.

Cartridge heater with a right angle block and a stress tube

b) Sometime, making a simple bow in the wire helps decrease tension in the cable, if the cartridge moves in the application and a small repetitive vibration occurs.

5. Contaminant in the environment:

Many contaminant sources can potentially reduce the usual service life of a cartridge: plastic, oil or a very dusty environment that came in contact with the sealant and the cartridge’s wires.

If you are in the food industry, be aware that if you water your equipment, moisture penetrates the cartridge and may cause early failure. An epoxy sealer with Teflon wires are standard when cartridges are used in the food industry.

Depending upon the contaminant, a wide choice of sealers, wires and sheath are available. Contact us to discuss further or visit this page to learn more: https://www.volton.com/en/product/heating-cartridges/24-cartridge-heaters.html

Always stock your cartridges in a dry place at 200C min.

6. Too high in density:

The maximum power density recommended (watts per square inch), depends on your operating temperature, material to be heated by the cartridge, etc.

Volton can help you determine the ideal density for your application. Also, you’ll be told the maximum wattage recommended for warrantee purposes in case of manufacturing defect of the cartridge. Keep in mind that not all manufacturers warn their client when a cartridge is too high in density. By doing so, you end up with early failure of your cartridge, without ever knowing why it happened.

7. Cartridge not completely inserted in hole:

Even if it includes a cold area which varies with its length, the stainless steel sheath of the cartridge must be completely inserted in the hole. If even a small hot area heats the air outside the mold, the cartridge is prone to burn quickly.

If you still don’t know the cause for your defective cartridges, gather your cartridges presenting early failure and send them to us for a diagnosis. We’ll open them up when necessary and put forward solutions to improve their durability to suit your application.

Skip site navigation

Skip site navigation